Transform the industrial workplace through connected safety Technology

Keep your workforce safe and projects productive.

Our workplace safety solutions deliver the critical intelligence and alerts necessary to maintain a secure operational environment and protect your workforce.

The dynamic oil and gas industry faces numerous challenges, including fluctuating global demand, production efficiency, volatile prices, stringent environmental regulations, and operational hazards. These challenges are further exacerbated by the risks associated with aging infrastructure and outdated technologies. The lack of real-time status updates for employees and field tasks, combined with incomplete visibility and communication gaps concerning hazards, accidents, contractors, precise remote tasks, and emergency situations, is driving significant changes in the industry.

Enhance site safety and compliance on projects.

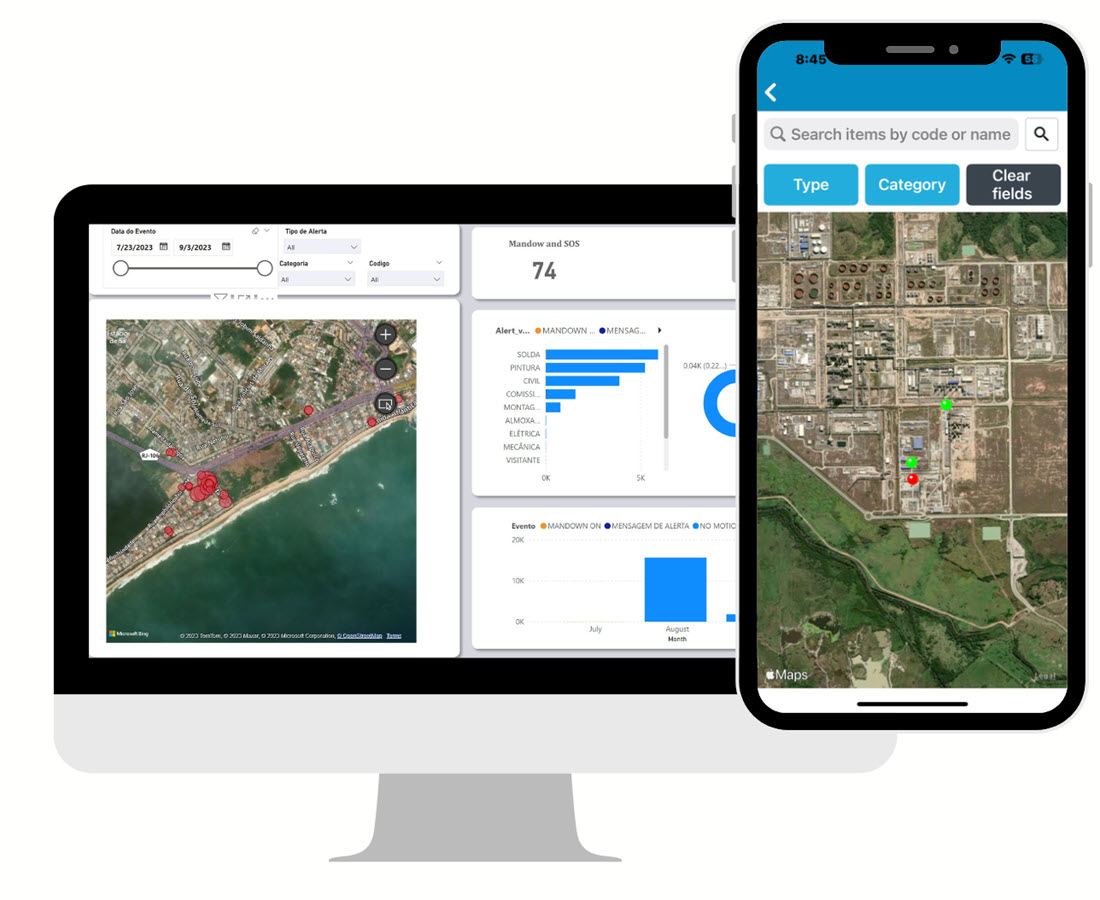

The Smartx HUB platform seamlessly integrates with equipment, software, IoT sensors, and other sources, enabling remote monitoring and real-time data visualization from a single command center. This technology-driven platform offers data-driven decision-making capabilities through AI-based predictive analytics and insights. By consolidating reliable data into a central source, it monitors and tracks workers, equipment, tasks, and maintenance procedures, improving operational performance, enabling rapid response, and ensuring correct actions for a safe and efficient environment.

Our Services

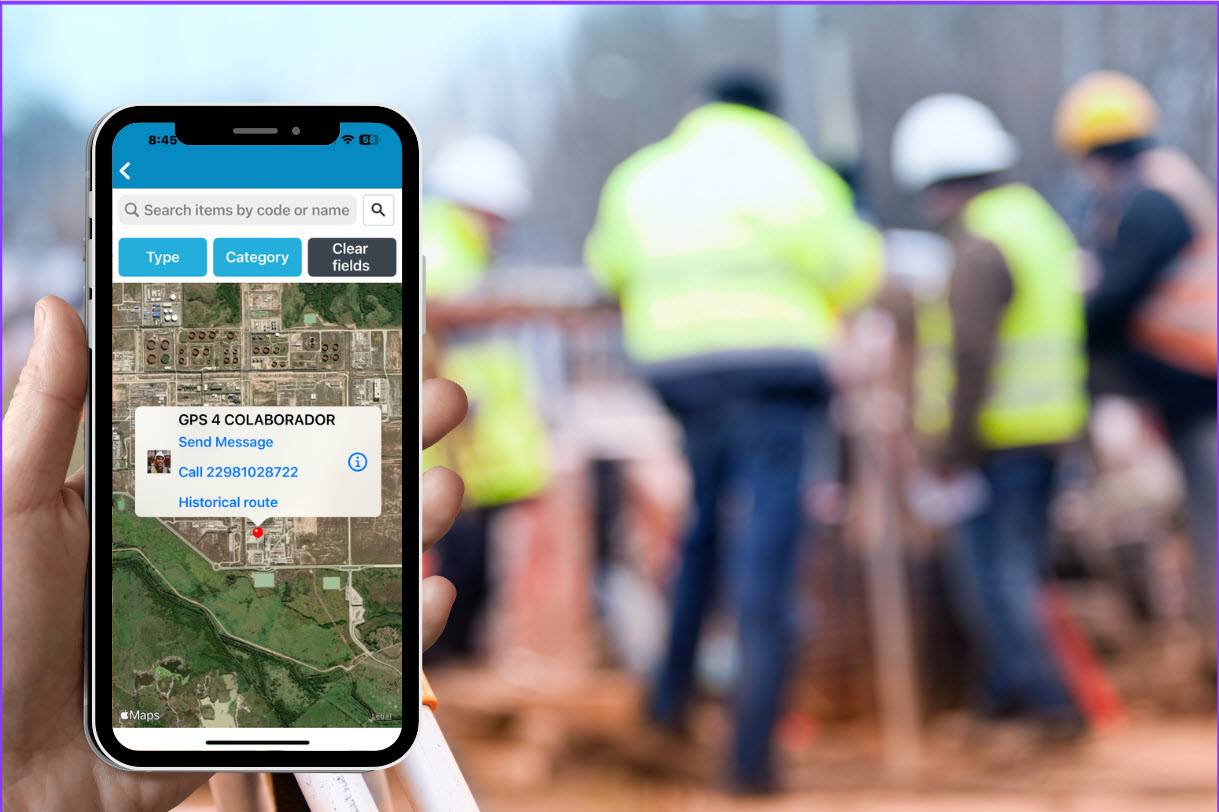

Real-time location

See your entire fleet on a single screen with the live map view. Simply log in and valuable situational information from all your devices is wearables and sensors at your fingertips at once.

Restrict high-risk zones

Know who is on your jobsite at all times so your project is safe and productive. Unlock real-time insights and alerts.

Emergency Management

Real-time information availability including emergency procedures and relevant safety documents for machinery operation and product handling.

Lockout Tagout

Our LOTO management solution automates and standardizes the full life cycle of the Lockout-Tagout process based on customer rules and regulations.

SOS Responses

If an alert is received, easily view the type, status, and location in real-time to help quickly find a worker in distress and understand the hazards they face.

Asset Management

Performance analytics and asset’s operational status for a clear view of the operation and accurate risk assessment.

Audits

Gain comprehensive insights into company-wide performance related to audits, inspections , and corrective actions.

Compliance Mandate

Comply with safety regulations for critical resources such as people or compliance-mandated equipment with historical data and reporting.

Operator Rounds

Dynamic forms and workflows allows for flexibility and ensure critical assets are always operational.

Smartx HUb is the only data-driven, interconnected, real-time data visualizationsolution to keep people safe and business thriving

Our SaaS-based Safety 4.0® platform offers predictive AI-powered digital safety solutions with a real-time view of a plant’s operational reality with superior visualization and dynamic work activities and risk management

The connectivity and software to further protect your team.

Next-level safety

Unmatched visibility

Enhanced productivity

Optimized Responses

Safety beyond compliance.

With Smartx HUB's connected safety solutions and data, you can review workers' risk exposure reports, analyze heat maps of hazardous incident locations, and track compliance trends over time. Unsure about the current calibration status of every critical asset in your operation? Smartx HUB provides real-time visibility into every connected device, enabling you to ensure the safety of your workers. With connected wearables that deliver data analytics for real-time compliance, you can be confident that you are not only compliant but also proactively improving the safety of your team.

Efficiently manage your workforce and trade partners using safety wearables, smart sensors, and a workforce management platform.

Minimize lost revenue and avoid safety incidents during turnarounds and shutdowns.

Whether it’s a planned turnaround, shutdown, or unforeseen outage, oil and gas facilities periodically need to take assets and processes offline and suspend production. This creates challenges for workplace productivity and safety for regular employees, as well as contract workers who are less familiar with the facility and its standard safety procedures. SmartX HUB utilizes data collected from your connected devices to identify opportunities to enhance operational efficiency and productivity during turnarounds or shutdowns, saving hours or even days of work to get assets back online faster.

The Connected Worker solution enables real-time interaction and facilitates optimized decision-making by identifying risks and implementing corrective and preventive actions. This leads to enhanced safety and improved performance.