Transform the industrial workplace through connected safety Technology

Keep your workforce safe and projects productive.

Our workplace safety solutions deliver the critical intelligence and alerts necessary to maintain a secure operational environment and protect your workforce.

Chemical manufacturing plants pose significant dangers to workers and the environment. Daily risks include exposure to toxic and highly flammable chemicals, leading to severe injuries from inhalation and burns. Mechanical failures, faulty valves and seals, chemical-based pipeline corrosion, and unmonitored processes can result in hazardous reactions and dangerous fumes. Issues such as contamination, improper labeling, and inadequate waste disposal further exacerbate these risks. Explosions, fires, and chemical spills may necessitate immediate response actions, including containment, emergency evacuation, and medical attention, and can cause severe environmental damage.

Connected worker, processes, and assets and keep compliance on projects and jobsites.

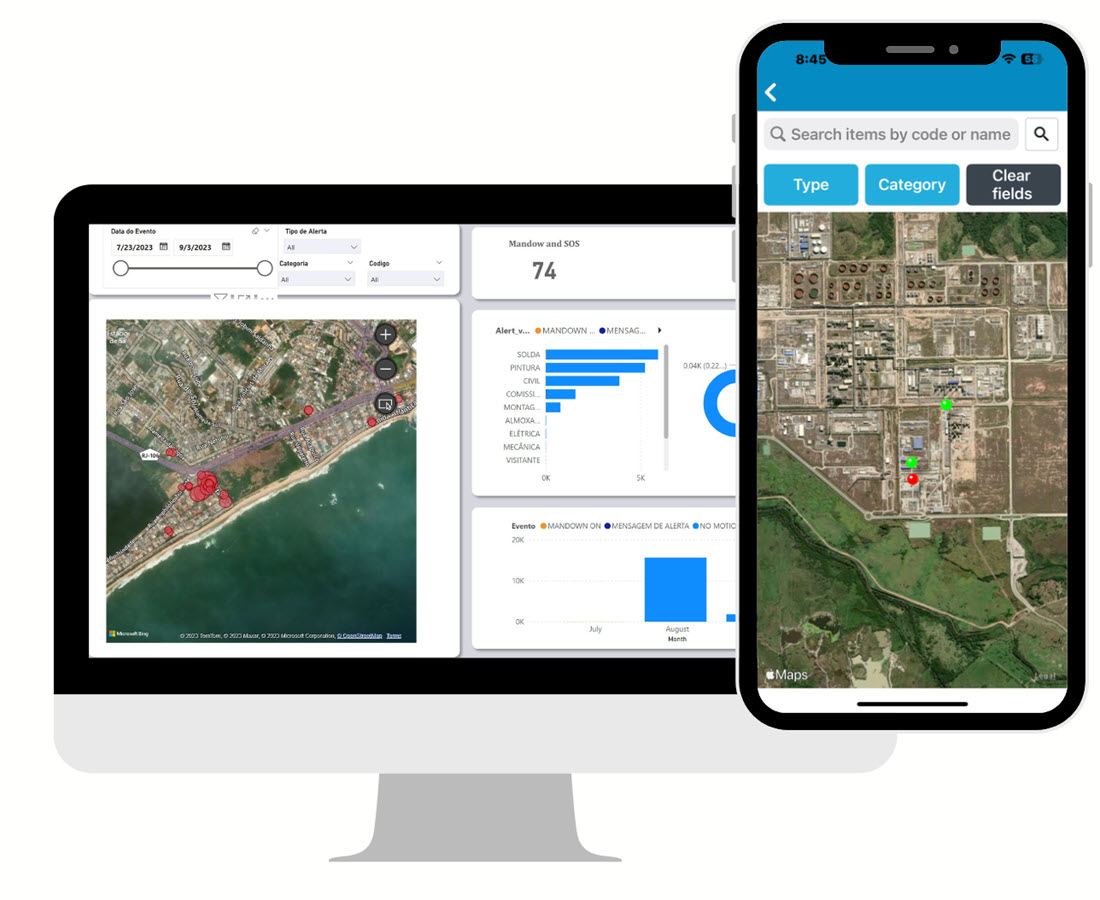

The Smartx HUB platform seamlessly integrates with equipment, software, IoT sensors, and other sources, enabling remote monitoring and real-time data visualization from a single command center. This technology-driven platform offers data-driven decision-making capabilities through AI-based predictive analytics and insights. By consolidating reliable data into a central source, it monitors and tracks workers, equipment, tasks, and maintenance procedures, improving operational performance, enabling rapid response, and ensuring correct actions for a safe and efficient environment.

Our centralized platform for process safety control and proactive risk management in the chemicals industry

SmartxHUB’s safety solution offers dynamic risk assessment and enhanced control of process safety for chemical-based activities. Real-time status updates for workers and processes enable critical, time-sensitive alerts. Access to information on hazardous chemical processes and incident-specific emergency procedures ensures rapid response in complex work environments. SmartxHUB’s proactive risk management addresses hazards from raw materials storage and chemical reactions, monitoring high-risk activities, equipment checks, and maintenance to prevent incidents and mitigate the consequences of emergencies.

Enhance efficiency with a digital , easy to use, holistic, flexible LOTO management solution

From preparation to full equipment restoration, our flexible solution adapts to any site or industry. The LOTO module allows operators, planners, and maintenance personnel to track, manage, and communicate lockout-tagout activities. Improve safety with real-time alerts for potential equipment manipulation during isolation. Boost productivity by preparing, verifying, and approving LOTO in advance. SmartX HUB’s LOTO management solution provides 24/7 access to real-time data in a single command center, connected to IT, IoT, IIoT, and ERP systems for timely, data-driven decisions.

Our Services

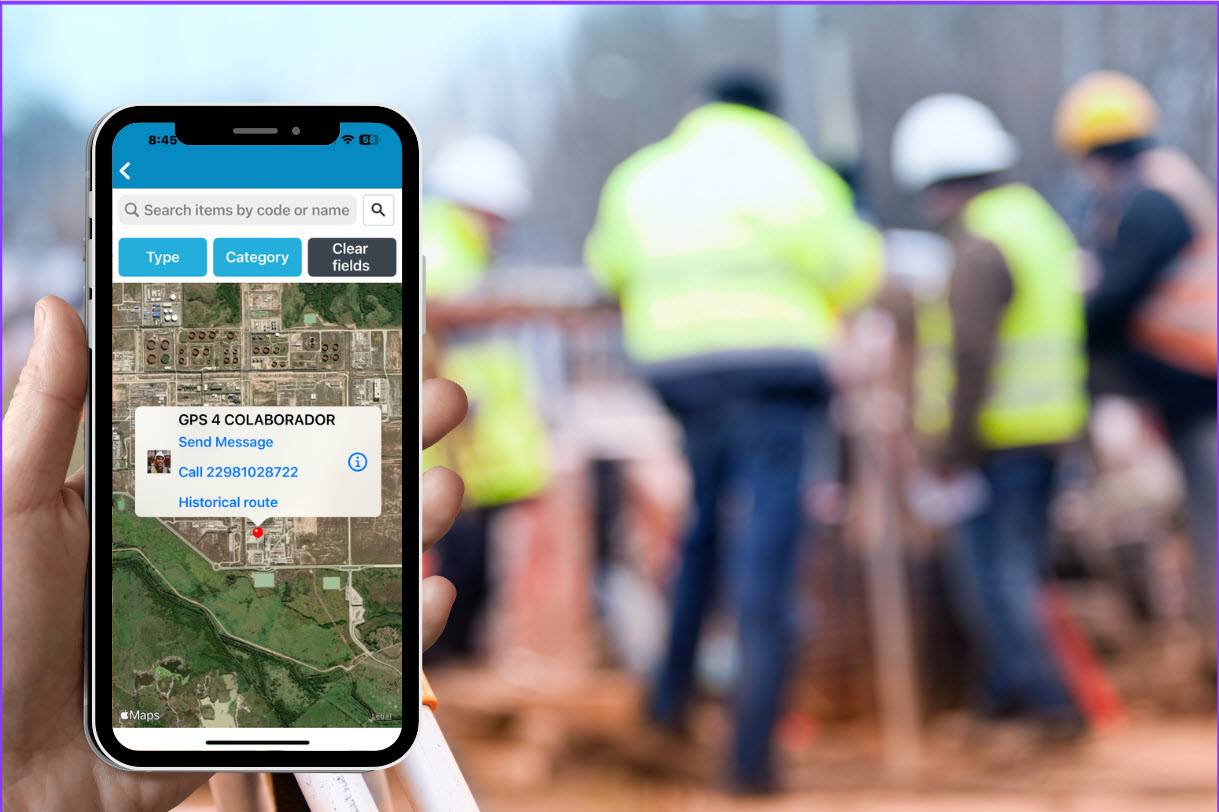

Real-time location

See your entire fleet on a single screen with the live map view. Simply log in and valuable situational information from all your devices is wearables and sensors at your fingertips at once.

Workforce management

Centralize worker and trade partner information and documents. Compare planned vs actual resources by trade using real-time data.

Emergency Management

Real-time information availability including emergency procedures and relevant safety documents for machinery operation and product handling.

Lockout Tagout

Our LOTO management solution automates and standardizes the full life cycle of the Lockout-Tagout process based on customer rules and regulations.

Restrict high-risk zones

Know who is on your jobsite at all times so your project is safe and productive. Unlock real-time insights and alerts.

Asset Management

Performance analytics and asset’s operational status for a clear view of the operation and accurate risk assessment.

Audits

Gain comprehensive insights into company-wide performance related to audits, inspections , and corrective actions.

Compliance Mandate

Comply with safety regulations for critical resources such as people or compliance-mandated equipment with historical data and reporting.

Operator Rounds

Dynamic forms and workflows allows for flexibility and ensure critical assets are always operational.

Smartx HUb is the only data-driven, interconnected, real-time data visualizationsolution to keep people safe and business thriving

Our SaaS-based Safety 4.0® platform offers predictive AI-powered digital safety solutions with a real-time view of a plant’s operational reality with superior visualization and dynamic work activities and risk management

The connectivity and software to further protect your team.

Next-level safety

Unmatched visibility

Enhanced productivity

Optimized Responses

Safety beyond compliance.

With Smartx HUB's connected safety solutions and data, you can review workers' risk exposure reports, analyze heat maps of hazardous incident locations, and track compliance trends over time. Unsure about the current calibration status of every critical asset in your operation? Smartx HUB provides real-time visibility into every connected device, enabling you to ensure the safety of your workers. With connected wearables that deliver data analytics for real-time compliance, you can be confident that you are not only compliant but also proactively improving the safety of your team.

Efficiently manage your workforce and trade partners using safety wearables, smart sensors, and a workforce management platform.

Gain data-driven insights , alerts, and analytics with real-time location

Gain real-time workforce management tools & alerts. Know who is on your jobsite at all times so your project is safe and productive.

Manage and flag high-risk zones, catch bottlenecks, and find critical path activities.

Automate manual check-in/out times and validate work hours on the job using real-time location. .

The Connected Worker solution enables real-time interaction and facilitates optimized decision-making by identifying risks and implementing corrective and preventive actions. This leads to enhanced safety and improved performance.